Gaseous stations dispense pressurized gaseous hydrogen into trucks at pressures of either 350 bar (5,000 psi) or 700 bar (10,000 psi), depending on the truck’s required onboard storage pressure (see figure). The benefit of the lower, 350 bar, pressure is it is easier to achieve, and the stations can be more resilient. The benefit of the higher, 700 bar, pressure is more hydrogen can be packed onto the truck and facilitating longer range and heavier cargo loads. Truck manufacturers determine the required hydrogen storage pressure.

When hydrogen is dispensed as a high-pressure gas, it is done at one of two pressures, denoted by H35 and H70 which stand for 35MPa and 70 MPa, respectively (please see the table for the pressure equivalent units of each). Note that the H35 and H70 designations only refer to the pressure of fueling and not the grade of fuel. Vehicles that fuel at 70MPa pack hydrogen gas at higher density and therefore have longer range. In terms of interoperability, H70 vehicles can fuel using a H35 dispenser as this is lower pressure, however the reverse case is not true. H35 vehicles cannot use a H70 dispenser.

H35 Trucks

These trucks store hydrogen in gas cylinders at 35 MPa. This lower pressure is easier to accommodate, and hydrogen stations, which have storage at 50 MPa push the fuel directly into the vehicles, without the need for a booster compressor (see figure).

H70 Trucks

Trucks that have 70 MPa on-board storage require that the station dispense hydrogen at very high-pressure, which is dispensed out of a high-pressure buffer storage system (see figure). The method of accomplishing this very high-pressure is dependent on whether the hydrogen is stored as a gas or a cryogenic liquid (see figures).

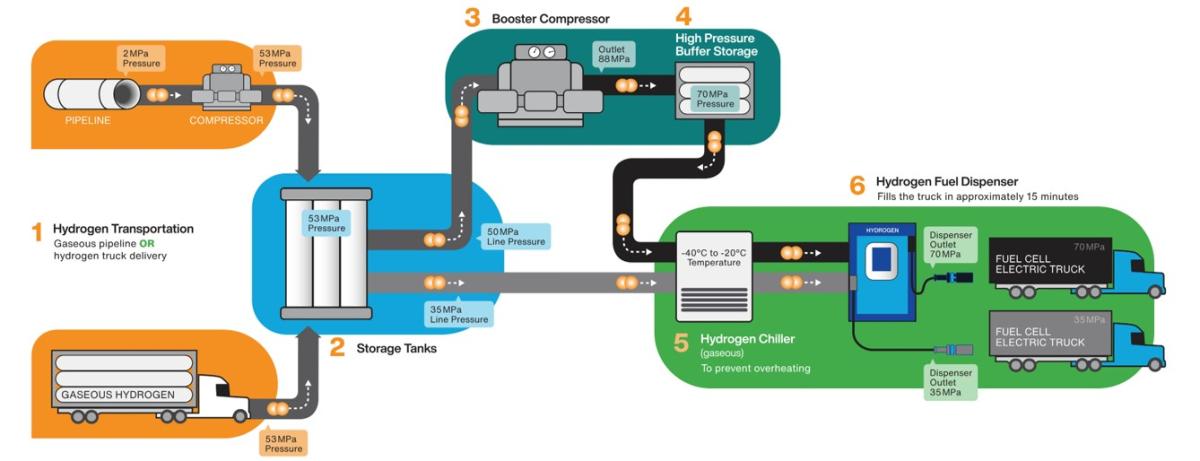

Hydrogen fueling stations that store hydrogen as a gas and dispense hydrogen as a high-pressure gas.

1. Hydrogen gas is delivered to the station in one of two methods, via pipeline (continuous delivery) or tube truck (in amounts on the order of 500 kg/delivery). If delivered by pipeline, the hydrogen must be compressed above the 500 bar pressure of the storage tanks (2). Gaseous hydrogen delivered by truck is at a pressure (520 bar) higher than the storage tanks (2) and therefore is bled into the gaseous hydrogen storage tanks (2).

2. Hydrogen gas is held in storage tanks at a pressure of 500 bar, with total storage capacity up to 800 kg.

3. and 4. The booster compressor and high-pressure buffer storage are necessary to fill vehicles that adhere to the SAE J2601, 700 bar storage pressure. If the vehicle’s filling pressure is 350 bar, then the booster compressor and high-pressure buffer storage are not necessary, as the station storage pressure exceeds this.

5. The chiller pre-cools hydrogen to -40°C, just before filling the vehicle. Hydrogen gas, unlike all other gases, heats up upon rapid expansion, therefore this pre-cooling step offsets the increase in temperature, as hydrogen expands into the vehicle tanks.

6. Hydrogen is dispensed to the truck at pressures of 350 bar or 700 bar, depending on the manufacturer. The dispensing nozzle is a sophisticated device that contains a communication link to the vehicle diagnostics, which the station uses to monitor the vehicle as hydrogen is dispensed.

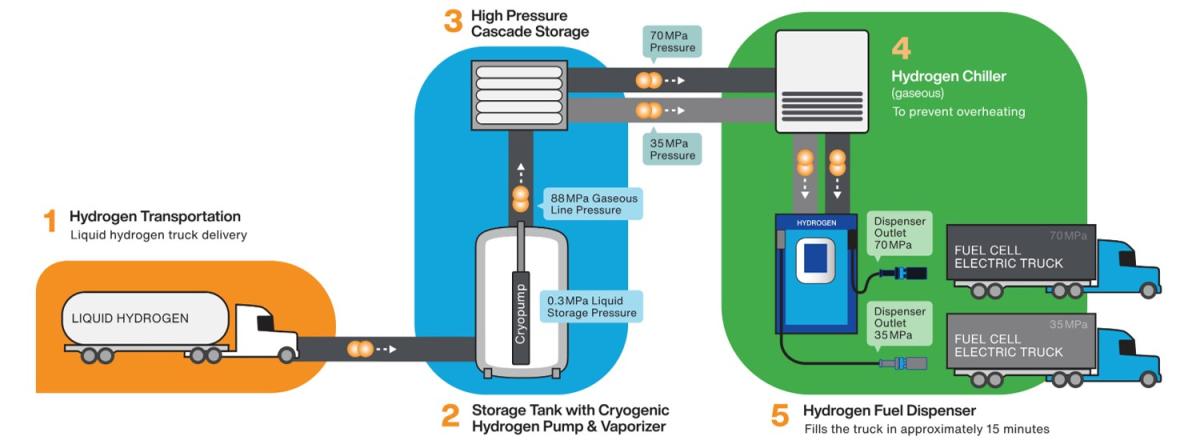

Hydrogen fueling stations that store hydrogen as a cryogenic liquid and dispense hydrogen as a high-pressure gas

1. Hydrogen is delivered as a cryogenic liquid (below -253C) to the station via a liquid hydrogen tanker truck in amounts of 1,000+ kg/ delivery.

2. Cryogenic liquid hydrogen is contained in an insulated storage tank at ambient pressure, with total storage capacity of 1,600+ kg. When hydrogen is needed, a cryogenic liquid pump pressurizes the liquid hydrogen to 875 bar and vaporizes it as a high-pressure gas into buffer storage (3).

3. High-pressure buffer storage is the intermediate step necessary to fill vehicles that adhere to the SAE J2601, 700 bar storage pressure. Vehicles at the lower, 350 bar can also be accommodated by this buffer storage.

4. The chiller pre-cools hydrogen to -40C, just before filling the vehicle, however the gas may already be cold due to the cryogenic nature of storage (2). Hydrogen gas, unlike all other gases, heats up upon rapid expansion, therefore this pre-cooling step offsets the increase in temperature, as hydrogen expands into the vehicle tanks.

5. Hydrogen is dispensed to the truck at pressures of 350 bar or 700 bar, depending on the manufacturer. The dispensing nozzle is a sophisticated device that contains a communication link to the vehicle diagnostics, which the station uses to monitor the vehicle as hydrogen is dispensed.

Note about gaseous hydrogen dispensing pressures

When hydrogen is dispensed as a high-pressure gas, it is done at one of two pressures, denoted by H35 and H70 which stand for 35MPa and 70 MPa, respectively (please see the table for the pressure equivalent units of each). Note that the H35 and H70 designations only refer to the pressure of fueling and not the grade of fuel. Vehicles that fuel at 70MPa pack hydrogen gas at higher density and therefore have longer range. In terms of interoperability, H70 vehicles can fuel using a H35 dispenser as this is lower pressure, however the reverse case is not true. H35 vehicles cannot use a H70 dispenser.

| Hydrogen Dispenser Button | Pressure Equivalents (in Megapascal, bar and psi) |

|

• 35 MPa • 350 bar • ~5,000 psi |

|

• 70 MPa • 700 bar • ~10,000 psi |