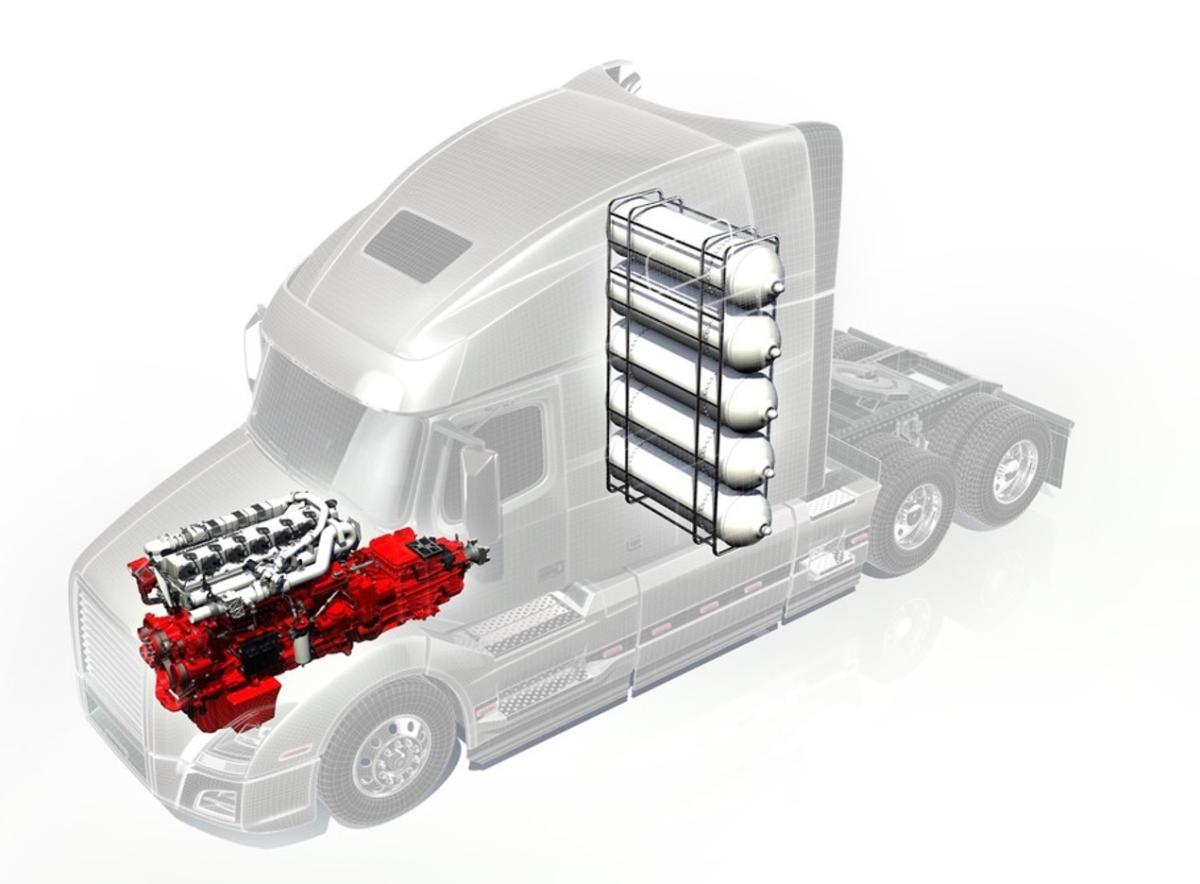

Hydrogen internal combustion engine (ICE) technology offers a potential low-cost, clean, alternative fuel. A major benefit is it potentially can be introduced at cost comparable to diesel trucks and use hydrogen at a cost that approaches diesel fuel. To reduce manufacturing costs, hydrogen engines are designed to use shared common diesel engine components below the head gasket (engine block, crank shaft, manifolds, etc.), and fuel specific components above the head gasket (cylinder head, fuel injectors, valve train, etc.). Hydrogen ICEs offer advantages such as high-power output, low emissions, robustness, low upfront costs and has higher tolerance to impurities in hydrogen fuel. This technology is particularly suitable for larger, higher-horsepower applications. The cost of hydrogen ICEs is forecasted to initially be lower than fuel cell technologies. However, as the technologies progress, this gap will narrow.

Several methods of combustion are in development including spark- and compression-ignition (with diesel pilot ignition) technologies. As these are combustion engines, they have some air pollution impact, however manufacturers are committed to minimizing these.

Hydrogen Combustion

One kilogram of hydrogen has approximately the same energy content as a gallon of diesel fuel. Hydrogen combustion in the presence of oxygen releases a significant amount of heat and water vapor. Since hydrogen does not contain carbon, there are no CO2 emissions, however the combustion process reacts with nitrogen in the air to form some NOx, which must be managed.

Hydrogen has an auto-ignition temperature of 1,085°F vs. gasoline’s 450°F vs. diesel’s 410°F, therefore hydrogen engines can achieve significantly higher compression ratios than gasoline or diesel, which translates to higher power output per engine stroke.